![]() The new Proel laser machine "e.Laser" works together with embroidery machine to create a very accurate and efficient system for fabric laser cutting and fabric laser engraving placed on the frame of the embroidery machine. This new laser system (patents pending solution) doesn't require electrical or mechanical changes on the embroidery machine.

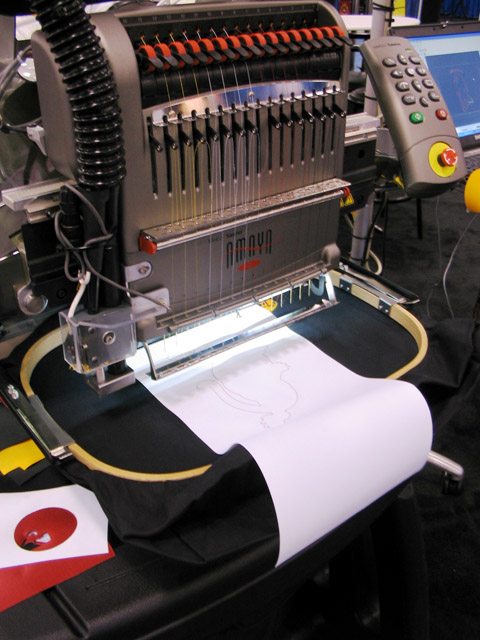

The new Proel laser machine "e.Laser" works together with embroidery machine to create a very accurate and efficient system for fabric laser cutting and fabric laser engraving placed on the frame of the embroidery machine. This new laser system (patents pending solution) doesn't require electrical or mechanical changes on the embroidery machine.

The laser system is able to work on the entire working area of embroidery frame. The "e.Laser" can be used for any type of production, from the small embroidery business, or craftsman studio (with a single head embroidery machine), to the large industry (multihead embroidery machines).

|

|

|

MAIN FEATURES

-

PATENTS PENDING SOLUTION

-

SIMPLE INSTALLATION AND CUTTING FILES CREATION

-

EASY INSTALLATION

-

NO MECHANICAL OR ELETRONIC MODIFICATIONS TO THE EMBROIDERY MACHINE

-

INEXPENSIVE SYSTEM

The e.Laser is a CO2 Laser machine equipped with a 25 or 50 Watt CO2 laser source. During the cycles of laser cutting and laser engraving, to the cutting head is sent a flow of air is sent to the cutting head in order to maintain clean the focusing lens, avoiding burnings on material: this in order to have very defined and clean cuts. The smokes produced during laser cutting or laser engraving, are evacuated by an external suction machine. The machine is equipped with a internal smoke suction device.

USABLE SOFTWARE for LASER CUTTING

Proel software for laser cutting FOCUSCUT III is the best program to manage laser cuts with e.Laser because the operator can use a lot of automatic tools for: auto-recognizing the embroidery edges, creating laser lettering and true type laser lettering, automatic creation of kiss cutting levels, etc. Possible also to manage the laser cuts with any client punching system.

TECNICAL SPECIFICIFICATIONS

| Electrical input |

1phase 220/240 Vac ±10% - 50/60Hz ±2%

|

| Absorbed power max |

3000 VA

|

| Dimensions (WxDxH) |

284x492x1253 mm

|

| Weight max. |

80 Kg

|

| Noise emission |

< 70 dB (with internal fumes suction unit)

|

| Working area (WxD) |

the same of embroidery machine

|

| Fumes extraction |

top suction system

|

| Fumes suction |

external and internal unit

|

| Laser source type |

CO2 - 10.6 µm - sealed type - RF Air liquid cooled

|

| Laser power |

25W / 50W

|

| Laser beam delivery | |

| Laser spot diameter |

140 µm

|

| Cutting speed |

depending on the embroidery machine

|

| Resolution |

the same of embroidery machine

|

| Optics cleaning |

internal or external air / external gas

|

| Software |

Focuscut III or client punching

|

| Laser product Class |

class 1 (EN-60825-1:2003-02)

class I (USA-CDRH 21 CFR) |

| Safety devices |

protective enclosures + laser beam stop access panel with safety interlocks

|

The Manufacturer reserves the right to make modifications and improvements without prior warning.

{youtube}NtPZ3gkrK7k{/youtube}

{youtube}lvVaFQUDss4{/youtube}